The journey of China’s BOPP cigarette films replacing imported products is a story of industrial upgrading and independent innovation. Since the 1990s, China’s BOPP cigarette film industry has transitioned from relying on imports to self-production and eventually to exporting. By 2003, Chinese BOPP cigarette films had fully replaced imported products, and China had become a major producer of various cigarette films with quality reaching an optimal level.

Hainan Shiner Industrial Co., Ltd. (SN) began its involvement in the BOPP cigarette film industry in 1991, supplying BOPP cigarette films to Chinese cigarette manufacturers. It was one of the four major cigarette film producers in China at that time. During this period, the cigarette industry primarily used standard BOPP cigarette films, and imported films held a significant market share. In early 1995, the Chinese cigarette industry began importing BOPP shrink films, which became the primary product used in cigarette packaging.

( Factory construction)

To develop high-quality BOPP cigarette films and a more comprehensive product range to meet the packaging needs of the cigarette industry, Hainan Shiner independently modified the production line imported from Japan, adding an auxiliary extruder and replacing the die head with a better-quality one from EDI.

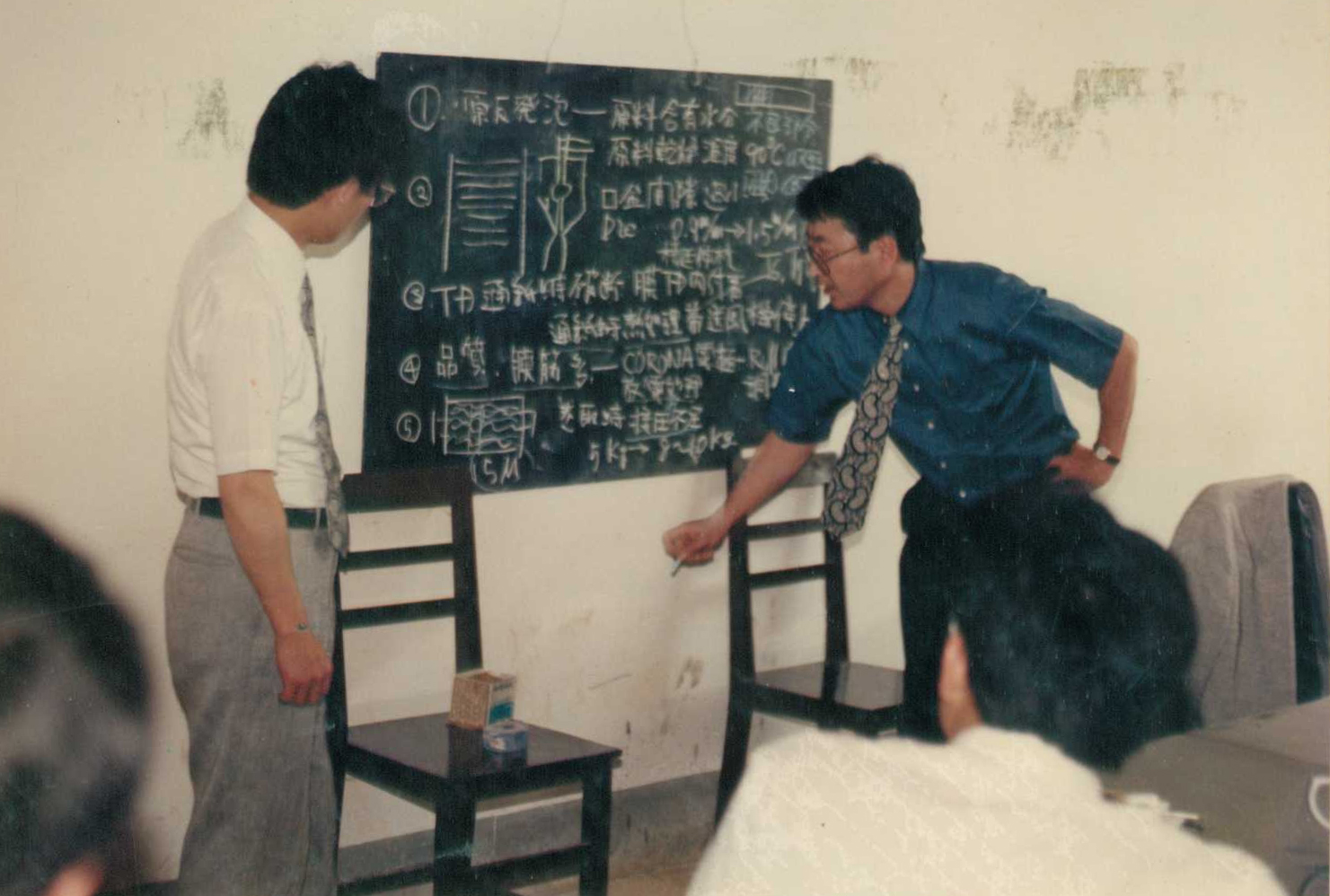

(Technical guidance during equipment installation))

Hainan Shiner continued to innovate independently and successfully developed BOPP cigarette shrink film in June 1995, becoming the first to replace similar imported products. This development reduced the price of imported shrink film from 55,000 RMB/ton to 32,000 RMB/ton. At the same time, the company developed a beautification device that made the shrink film fit more closely to the cigarette pack during the packaging process, enhancing the premium appearance of the cigarette. This device has now become a standard feature on cigarette packaging equipment both domestically and internationally, making a significant contribution to the development of the domestic tobacco industry.

(BOPP shrink film produced by SN in 2002, exhibited at the Shanghai Tobacco Museum)

In 2012, Hainan Shiner upgraded its BOPP cigarette film production line, becoming the only company in China to customize a production line specifically for BOPP cigarette films. With over 30 years of development in the cigarette film industry, Hainan Shiner has built a strong production technology team and a robust capability for new product innovation, becoming a major producer of cigarette films both domestically and internationally.

(The world’s first high-quality cigarette film production line, custom-made by Brückner in Germany)

-

Shiner Presents at World Tobacco Middle East 2025

On November 11, 2025, our international marketing team participated in the World Tobacco Middle East 2025 exhibition (Booth T186) in Dubai, engaging in in-depth exchanges with global tobacco industry partners and exploring business opportunities. We also presented Chinese gifts.

2025-11-12

-

Contact Us

Hi-Tech Zone, Hainan, China

Email:zhuhaiyan@shinerinc.com

Tel: +86-0898-6858 1104

Fax:+86-0898-6858 5861