Accelerating the journey towards sustainable development through the research and application of eco-friendly materials, we are committed to exploring packaging solutions that are kinder to both the Earth and its inhabitants, supporting the achievement of carbon neutrality goals.

We are dedicated to the research, development,

and production of green, eco-friendly new materials that help our customers to lower the carbon footprints of their products and move toward a circular economy.

Fully biodegradable

Free from colored metals

Odor-free

Superior moisture resistance and aroma retention

Excellent printability with a wide range of inks

Made from bio-based materials, fully biodegradable, low carbon,and environmentally friendly.

PLA Tobacco Film

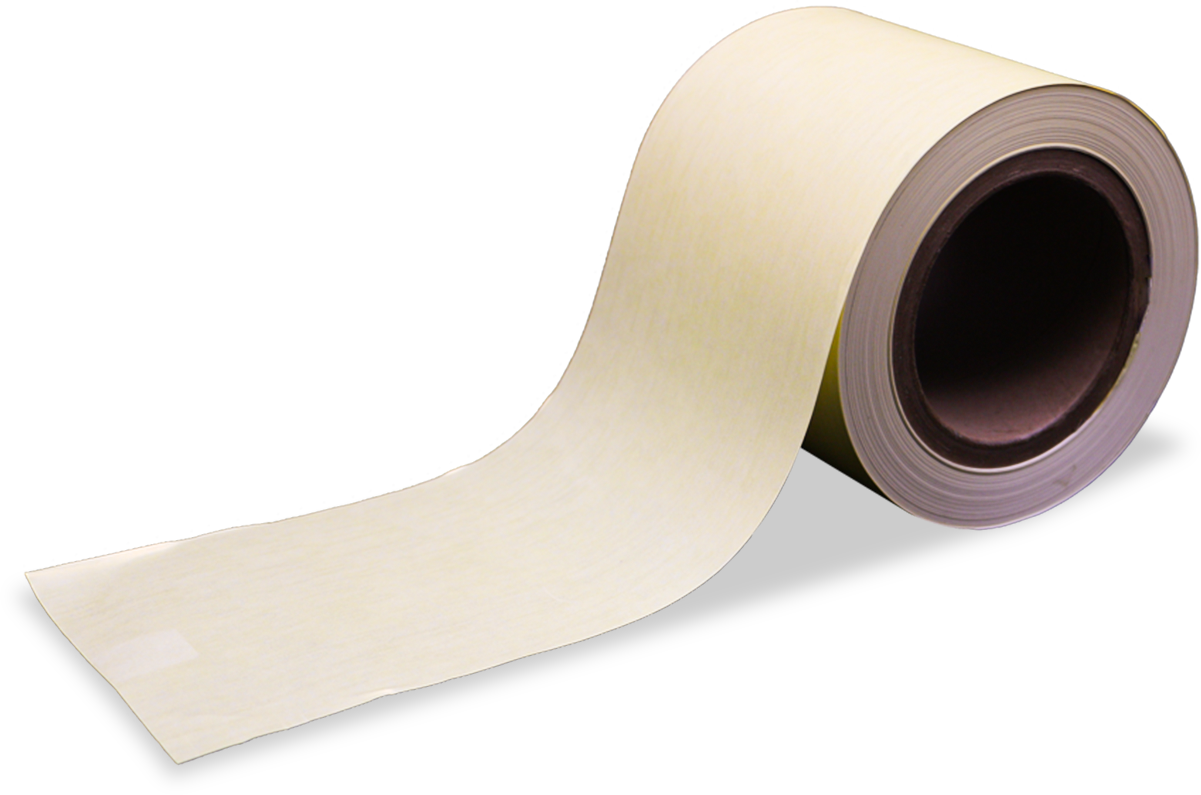

PLA Filter Tow

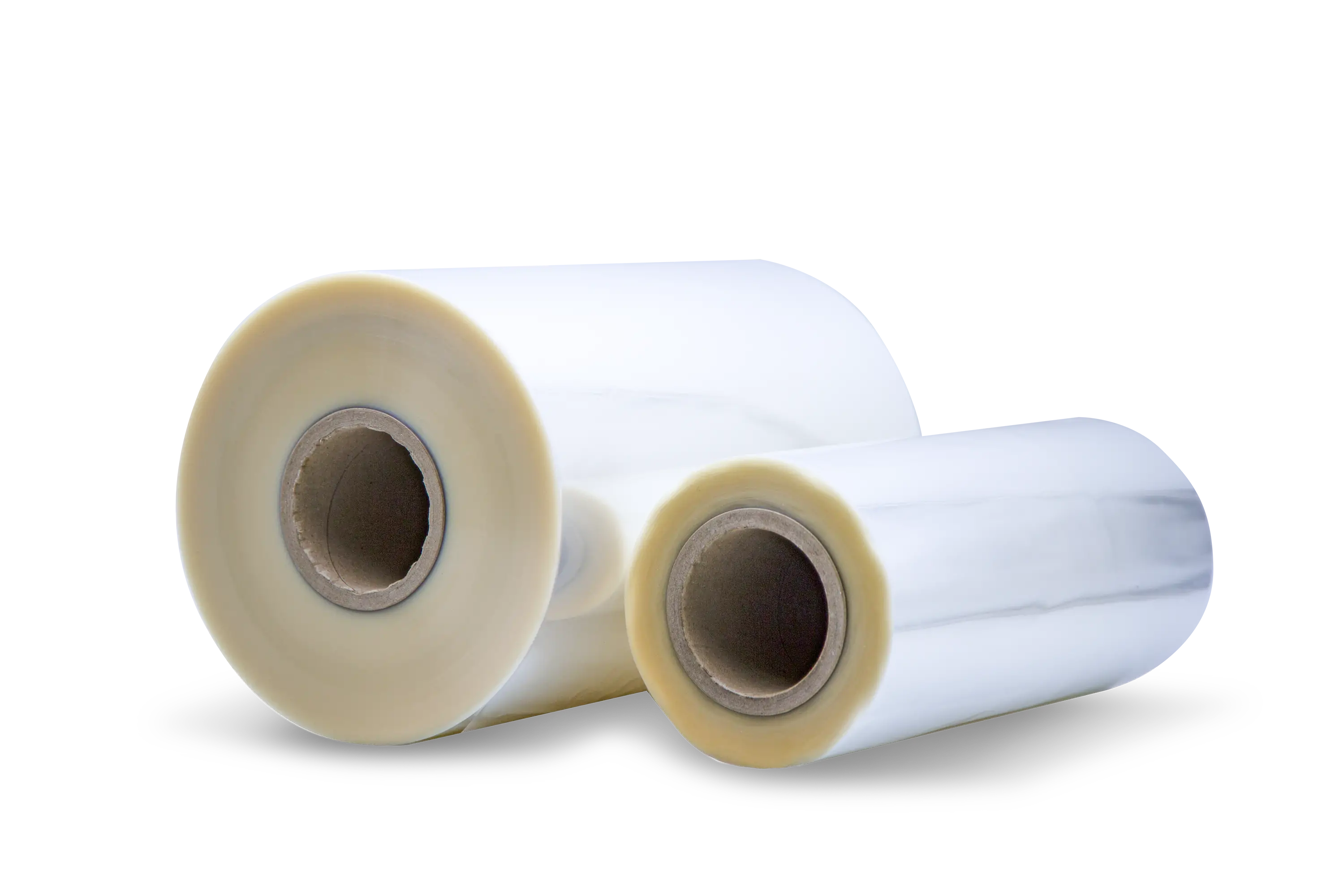

PLA Shrink Film

PLA Mulch Film

PLA Food Containers

PLA Modified Atmosphere Packaging Film

label paper/inkless prints

Safe printing packaging. There are no VOCs residuals in the printing packaging products, which conforms to the packaging safety standards for food and medicine.

A safe and environment-friendly mode of production that reduces and eliminates organic emissions during printing and production processes.

Polylactic acid is produced by fermenting starch-based biomass such as corn and tubers, or straw cellulose into lactic acid, then converting lactic acid into a cyclic dimer called lactide, and finally polymerizing the lactide through ring-opening polymerization to produce polylactic acid.

Innovative Green Materials

The new material, non-aluminum innerliner, is free of aluminum and adhesives, meeting personalized needs. According to some research and Life Cycle Assessments (LCA), packaging materials without aluminum can reduce carbon emissions by about 50% to 70% during the production process.

Overall life cycle energy consumption:

For traditional packaging materials :

The overall life cycle energy consumption is approximately 6.4 tons of standard coal per ton of product.

For Aluminum-free Innerliner:

The overall life cycle energy consumption is approximately 2.3 tons of standard coal per ton of product.

Polylactic acid is produced by fermenting starch-based biomass such as corn and tubers, or straw cellulose into lactic acid, then converting lactic acid into a cyclic dimer called lactide, and finally polymerizing the lactide through ring-opening polymerization to produce polylactic acid.

The new material, non-aluminum innerliner, is free of aluminum and adhesives, meeting personalized needs. According to some research and Life Cycle Assessments (LCA), packaging materials without aluminum can reduce carbon emissions by about 50% to 70% during the production process.

PLA Degradation Tobacco Film

Traditional packaging materials (including aluminum foil): The energy efficiency ratio is approximately 1:2.67 (meaning that for every unit of energy input, 2.67 units of product are produced).

Production energy consumption:

For traditional packaging materials :

Recycling energy for 1 ton of traditional aluminum-containing lining paper = 0.8 tons of standard coal energy

For Aluminum-free Innerliner:

Recycling energy for 1 ton of aluminum-free Innerliner = 0.2 tons of standard coal energy

For traditional packaging materials (aluminum-containing):

1 ton of traditional aluminum-containing innerliner production

energy = 3 tons of standard coal energy

For Aluminum-free Innerliner:

1 ton of aluminum-free Innerliner production energy = 1.5 tons of standard coal energy

Energy consumption from recycling and reuse:

Starting in 2023, Hainan Province, China, has seen green electricity account for over 65% of its total electricity consumption.

By the end of 2023, Hainan's installed capacity of clean energy power generation, including natural gas and nuclear power, reached 11.2066 million kilowatts, accounting for 75.22% of the province's total installed power capacity, with green power sources making up 39.79% of the total. In 2023, the province's total electricity generated and supplied to the grid was 42.674 billion kilowatt-hours, of which 27.88 billion kilowatt-hours came from clean energy, representing 65.33% of the province's total grid-connected electricity.

Promotion of New Energy Usage

Provide 10 new energy charging stations to encourage employees to use EVs, reducing reliance on traditional fuel vehicles and thereby lowering greenhouse gas emissions.

Photovoltaic Power Generation

Solar photovoltaic panels installed on the roof convert renewable energy into electricity for building use. Considering the solar radiation intensity of Haikou City, with 1248.56 annual effective utilization hours, the photovoltaic power generation fully meets daily operational needs,

and a battery storage system is employed to store excess energy.

Factory Electricity Usage

Through energy transformation, we have reduced the electricity consumption per ton of product from 920 kWh to 780 kWh, achieving a decrease of 140 kWh per ton and a corresponding reduction of 105 kg of CO2 emissions.

SN Aids China in Achieving Carbon Neutrality by 2060

In September 2020, China set clear goals to peak carbon emissions by 2030 and achieve carbon neutrality by 2060. SN will implement standards in material selection, film design, manufacturing, usage, and post-use recycling to realize low-carbon emissions throughout the entire lifecycle. Through technological innovation, SN will develop more safe, reliable, environmentally friendly, and low-carbon products to actively practice the "dual carbon" goals and contribute to the sustainable development of the industry.

Energy Audit and Management System

In 2022, SN took the lead in obtaining the industry's first Indoor Gas Emission Verification Statement Certificate.

In 2021, SN established a dual carbon task force to systematically study knowledge related to peaking carbon emissions and achieving carbon neutrality, receive professional training, and has obtained professional certifications such as Carbon Emission Manager.

ISO 50001 Energy Management System Certification

ISO 14064 Carbon Emission System Certification

Energy Efficiency Improvement

Waste Management and Recycling

Optimize production processes to reduce energy consumption and waste production. Lower the reject rate to 1%

We recycle 5% of film trimmings online and recycle all waste into granules.

Purchase energy-saving and environmentally friendly materials and products, and encourage our suppliers to adopt eco-friendly production methods.

We are dedicated to building a responsible, transparent, and sustainable supply chain. We encourage suppliers to join and accept assessments from SN. (SN has signed a sustainable cooperation agreement with Suzhou Advance Printing Limited)

We take full account of geographical location, climatic characteristics, and cultural heritage, adopting architectural strategies and technologies that are suited to the local environment. This approach creates a healthy and comfortable working and living environment, enhances energy efficiency, and promotes ecological balance.

Three-dimensional greening

The building's facade is equipped with a metal tension net, which not only provides effective shading but also enhances the facade's visual appeal, creating dynamic light and shadow effects inside as the sunlight changes throughout the day. Green plants are cultivated on terraces and rooftops to offer natural insulation, rainwater collection, and air purification, improving the site's ecological environment.

The building uses eco-friendly and recyclable construction materials, low�emissivity glass windows for enhanced insulation and lighting, and renewable eco-stone-like soft porcelain for the exterior walls.

An 130 sqm ecological pond is created in the park, effectively reducing the urban heat island effect through evaporation cooling, reflecting solar radiation, and heat storage, improving the urban thermal environment, enhancing quality of life, and promoting the health of the urban ecosystem.

In the initial furniture selection, consideration is given to future space utilization, and through the design and selection of water-saving fixtures, 1,305,200 liters of water are saved annually.

Introduce native plants adapted to Hainan's local conditions, reducing water consumption by more than 60% and pesticide and fertilizer use by more than 70%.

Our commitment to sustainable development

We aim to reduce absolute carbon emissions by 5000 tons;

increase the proportion of green electricity usage by 50%;

achieve Sustainability Certification;

enhance the proportion of green sustainable products by 50%;

invest 300 million yuan in sustainable material research and development and energy-saving emission reduction promotion.